Multi-Gauging Systems manufactured by our organization is reckoned for their optimum functionality by all our customers. Our organization is known for offering a premium quality range of Electronic & Multi Gauging Fixtures which is manufactured using certified components. Gauges supplied by us are at par with international standards of quality. Made available in various sizes and specifications, these multi-gauging fixtures are designed and developed with the aid of a proficient team of engineers and technicians

Multi-Gauging Systems manufactured by our organization is reckoned for their optimum functionality by all our customers.

READ MORE>>Multi-Gauging Systems manufactured by our organization is reckoned for their optimum functionality by all our customers. Our organization is known for offering a premium quality range of Electronic & Multi Gauging Fixtures which is manufactured using certified components. Gauges supplied by us are at par with international standards of quality. Made available in various sizes and specifications, these multi-gauging fixtures are designed and developed with the aid of a proficient team of engineers and technicians.

Less>>

Front Axle Beam Ht. & I.d. Inspection Gauge

Cylinder Block & Cylinder Head Computerized Multi-Parameter Inspection Station

Backlash / Shim Selecttion Gauge

Axial play Automatic Gauging

Four Jet Air Plug gauge

Knuckle component Multi-Gauge

Computerized Shaft All O.D. Inspection System

Automatic gauging for Cylinder Head & Block

Shim/Circlip Calculating and Selecting gauge

Taper Angle & Gauge Plane Ht./Gauge Dia. checking gauge

Shim Selection Gauge

Others

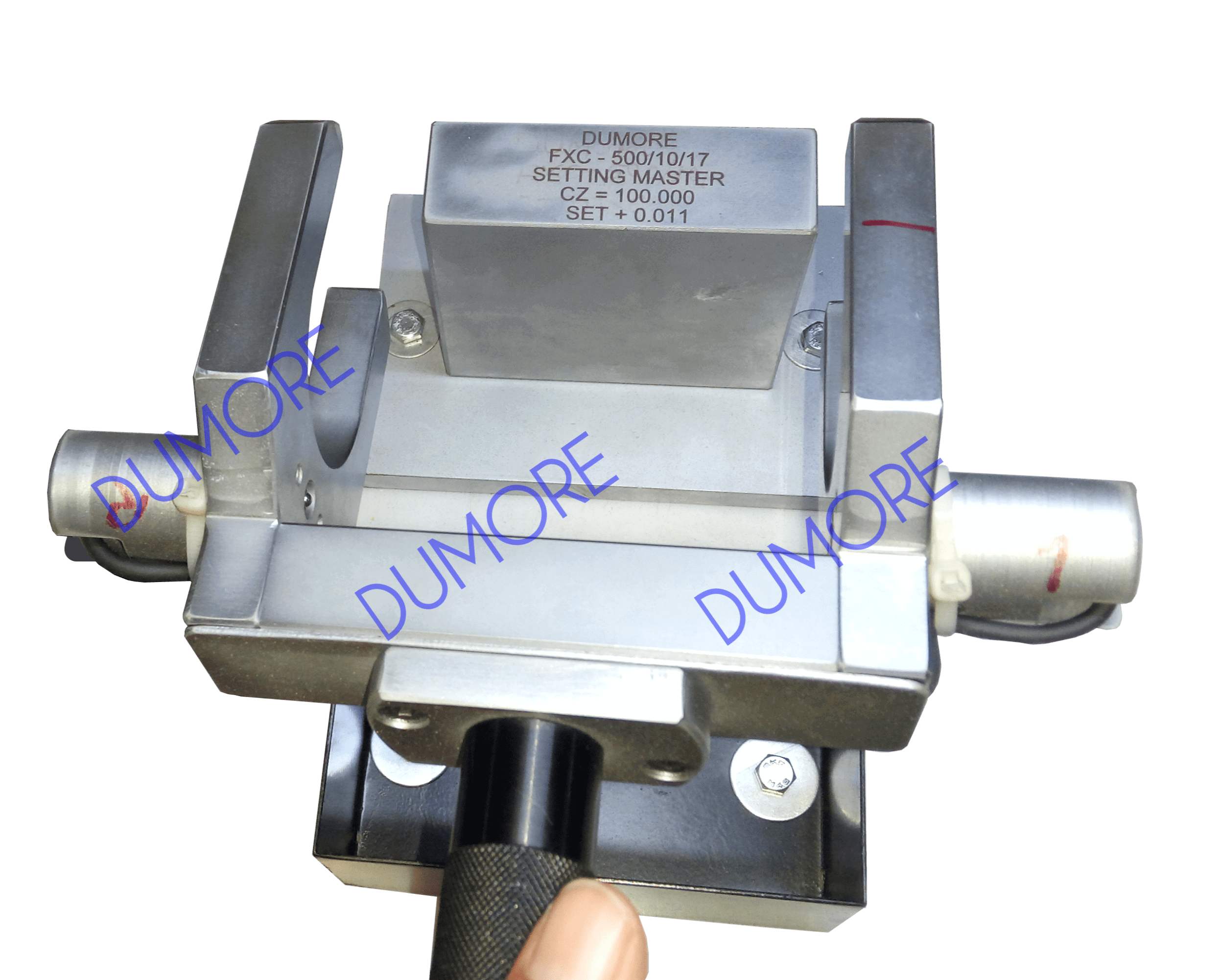

SHIM SELECTION GAUGE

Description :

- Knuckle Width and Beam Height are being checked.

- SHIM value is Auto Calculated and Displayed.

- Can give the signal for activation of other devices through signal processing unit and can accept different sensors o/p.

Parameters Checked :

- Parameters checked in Knuckle- Total Width with circumferential variations.

- Parameters checked in Beam - Total Height with circumferential variations.

Features :

- Fitted directly onto Assembly line.

- Light weight and durable.

- Small cycle time and very precise.

- SPC system maintains all records lifelong.

- Operator friendly.

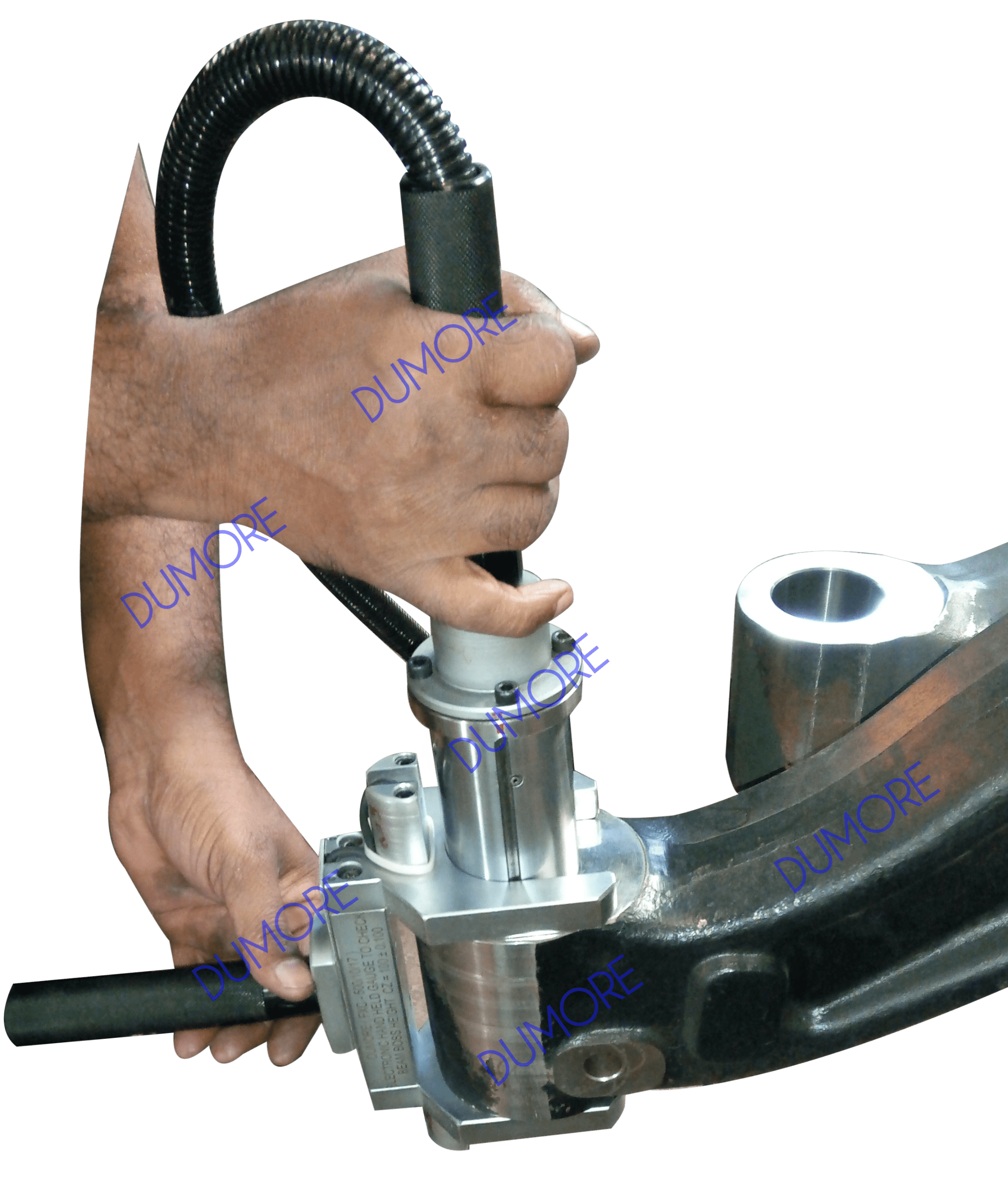

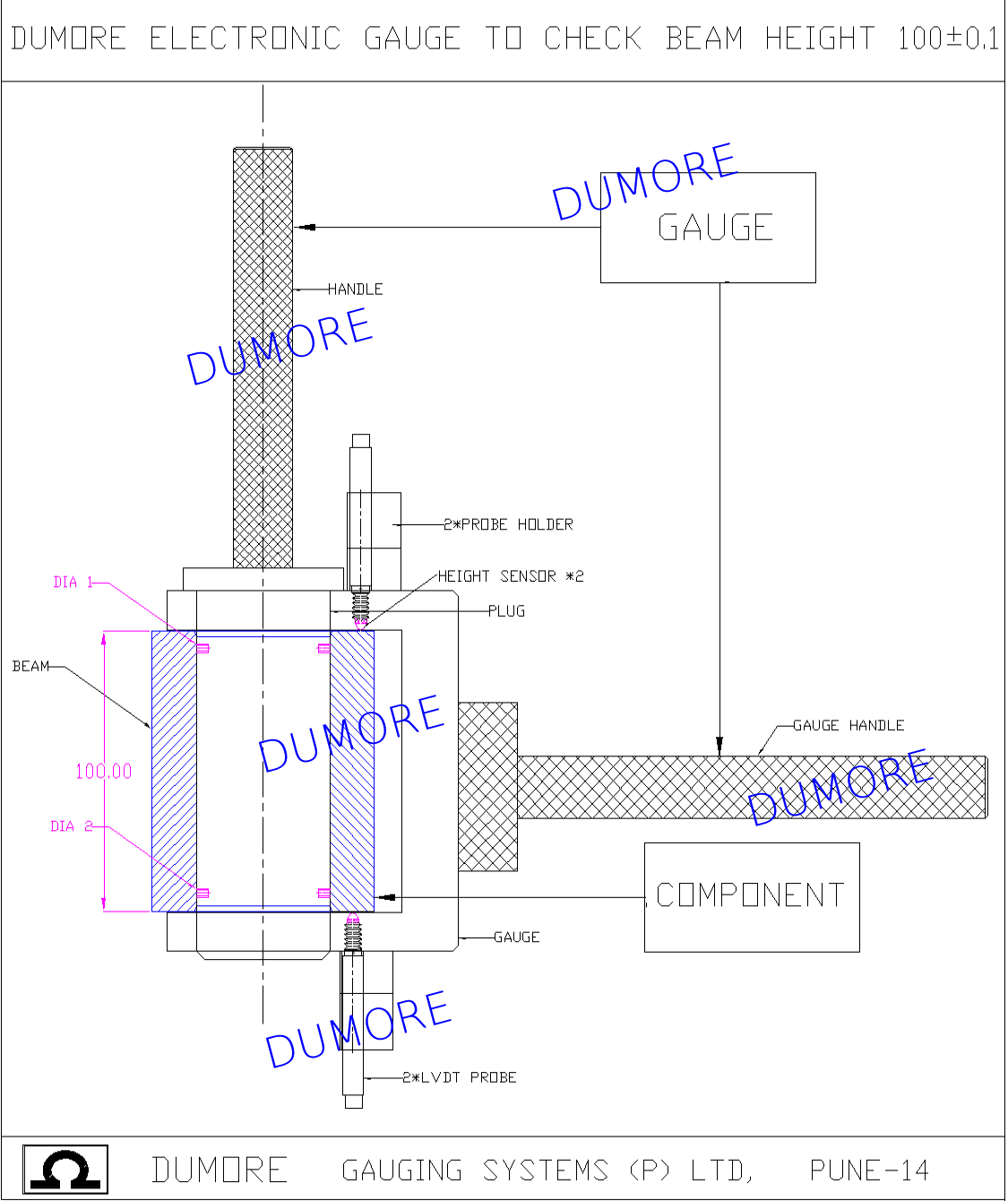

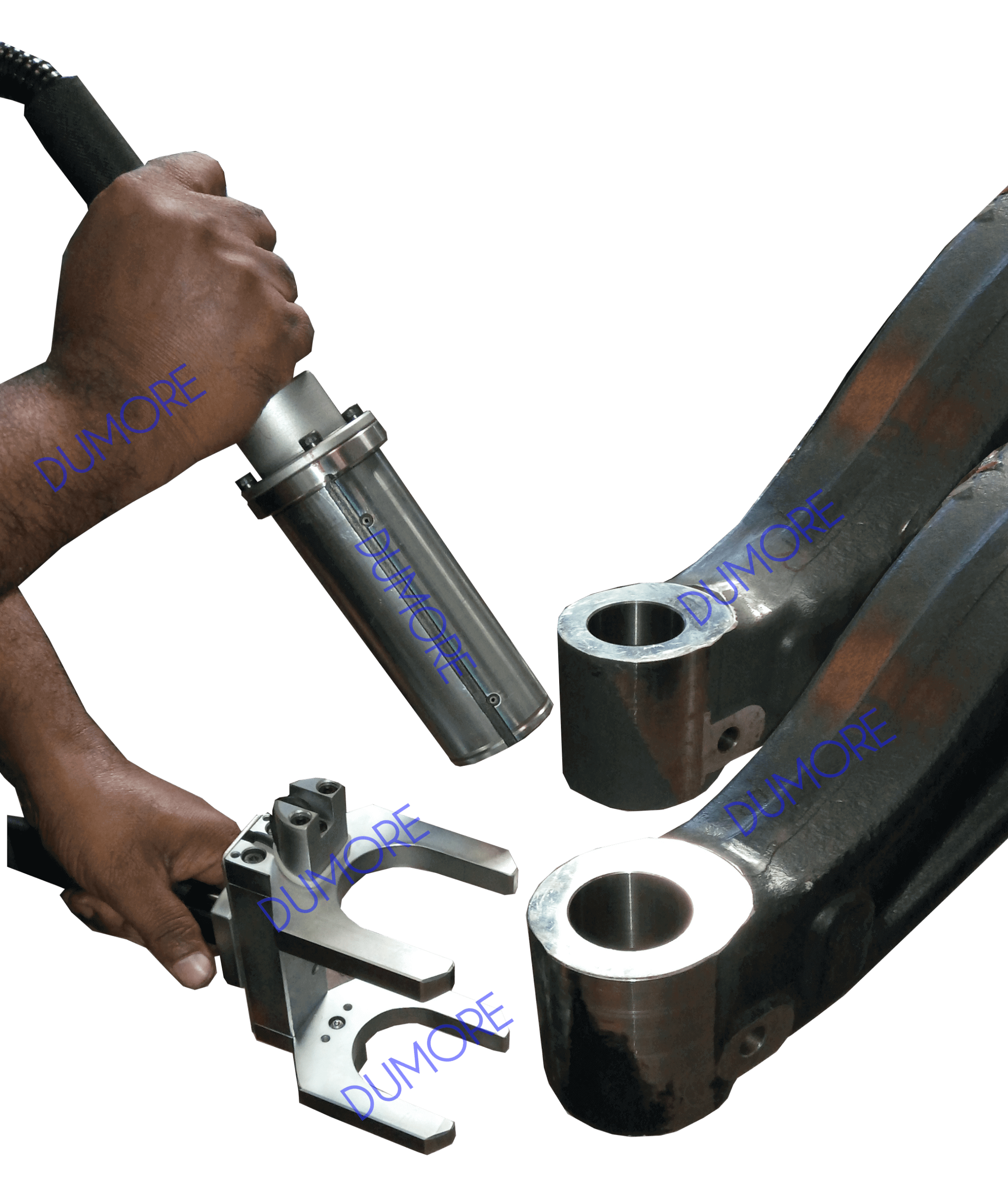

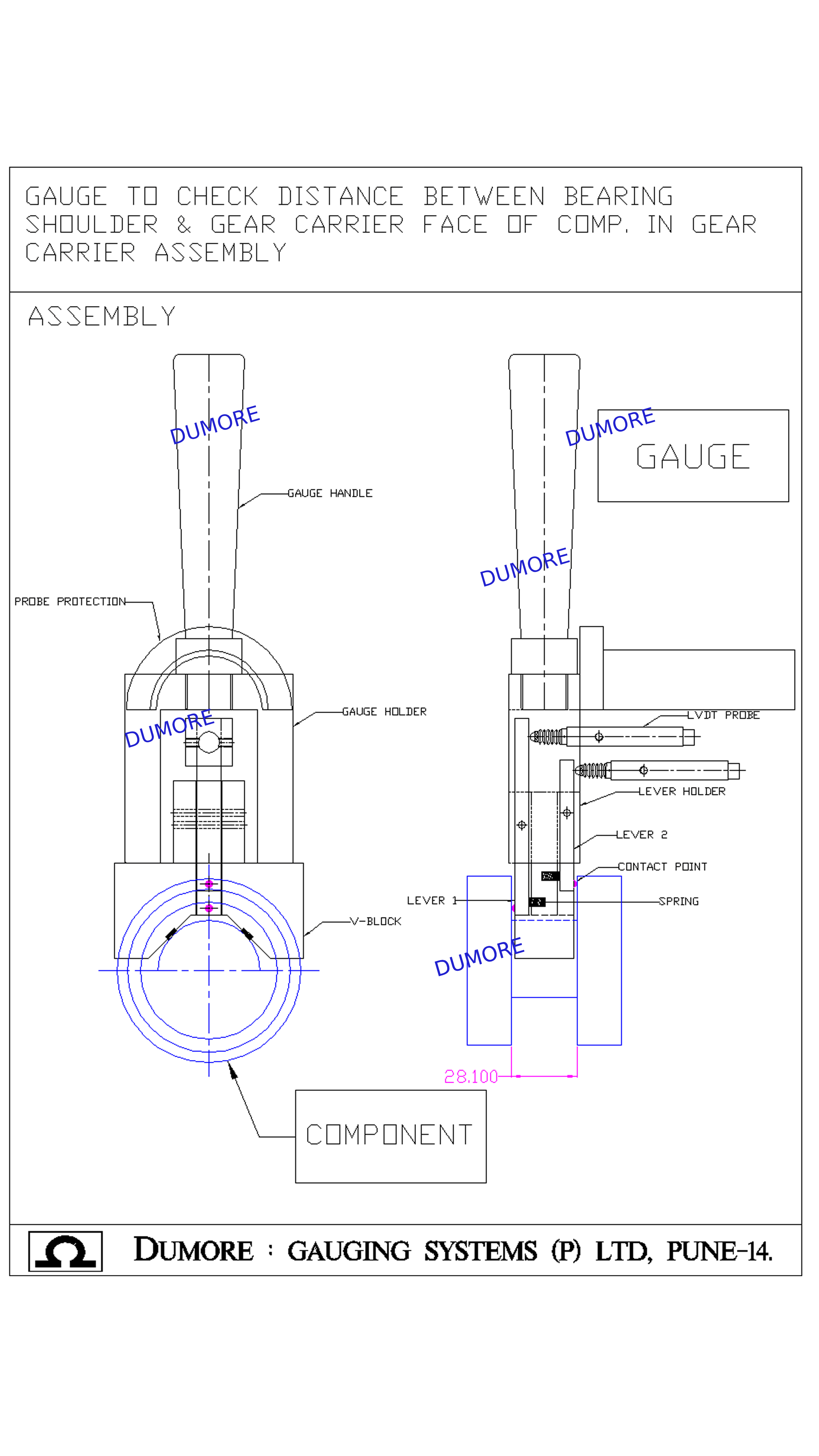

FRONT AXLE BEAM HT. & I.D. INSPECTION GAUGE

Description :

- Beam Height and Inner Diameter is checked at same time.

- Pure Electronic gauging system.

Parameters Checked :

- Total Height with Circumferential variations

- ID- At Two places

- Taper along full height of Beam

- Ovality at Two places.

Gauge fixture Features :

- Both LH and RH of Beam can be checked.

- Light weight and durable.

- Small cycle time and very precise.

- Operator friendly.

- Fitted directly next to Machine output.

- SPC system can be integrated.

Display unit features :

- Six probe input.

- Display is Specially Large Size Output with OK & NOT-OK LED Output.

- RS232 port ready (for connecting to SPC software at later stage)

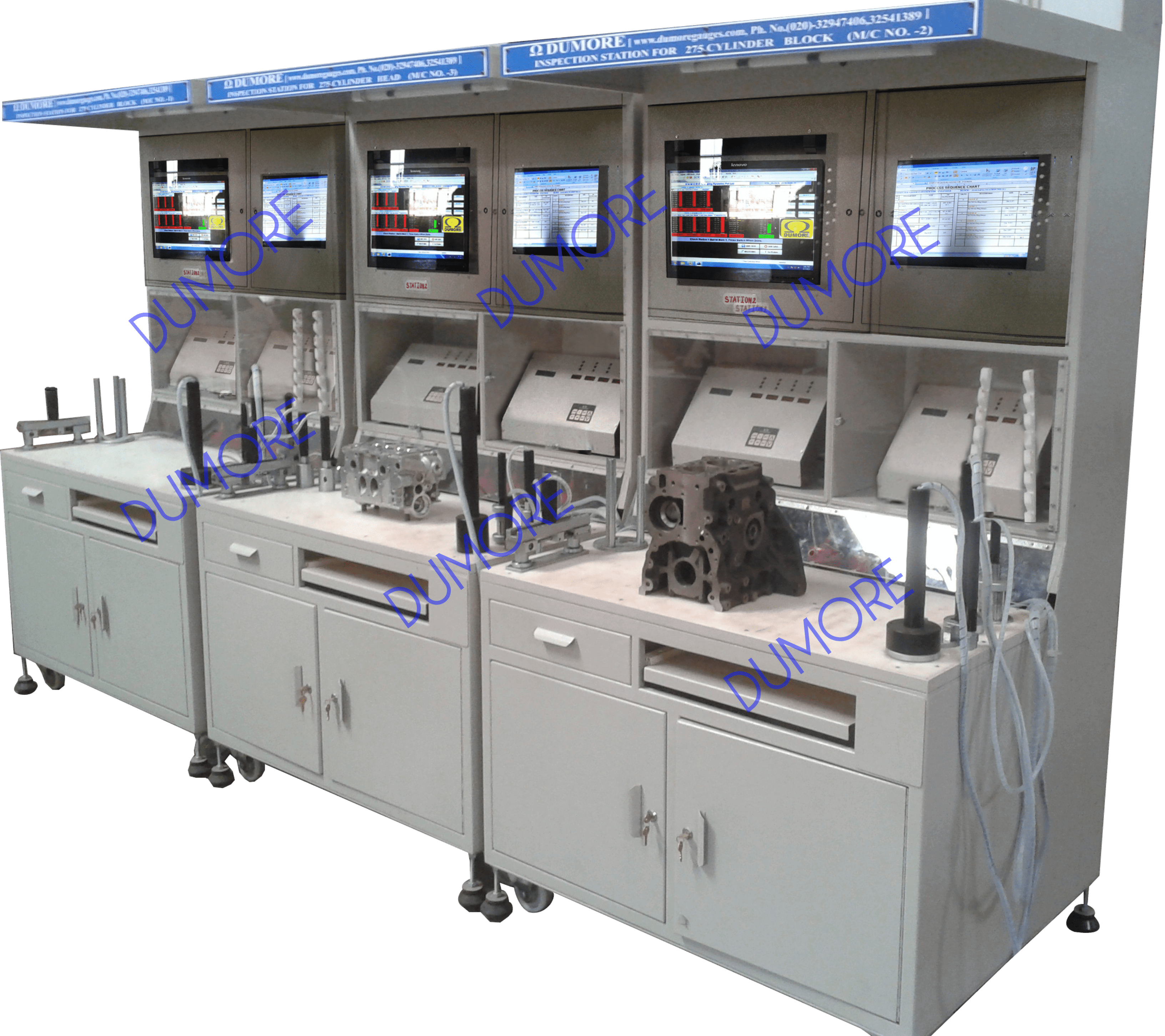

CYLINDER BLOCK & CYLINDER HEAD COMPUTERIZED MULTI-PARAMETER INSPECTION STATION

Description :

- Handheld combination gauges for checking multiple parameters at a time.

- All critical parameters are covered by this.

Parameters Checked :

- Barrel Bore Dia.& Head Face Height.

- Crank Bore Dia. with concentricity.

- Thrust Face Width.

- Special Two Monitor System.

- Oil Seal Depth, Concentricity of Cam Bore with Oil Seal Bore.

- PC chamber Dia.

- Valve Guide Dia.

- Head Face Dowel CD.

- Intake & Exhaust Valve Seat Depth.

- BC Face Height & CD to Dowel.

Features :

- Simple usage for operator to understand.

- All gauge values are displayed on the computer monitor sequentially.

- Light weight and durable.

- Small cycle time and very precise.

- SPC system maintains all records lifelong.

BACKLASH / SHIM SELECTTION GAUGE

Description :

- LH & RH Width inside the differential is checked.

- Considering the required backlash value to be maintained, our microcontroller unit uses predetermined formula to display Shim size for assembly.

Parameters Checked :

- LH & RH width inside the differential

Features :

- Very robust build for usage in the factory floor area.

- Easy, light weight and durable for operator to use.

- Fitted directly onto Assembly line.

- Small cycle time and very precise.

- SPC system can be integrated.

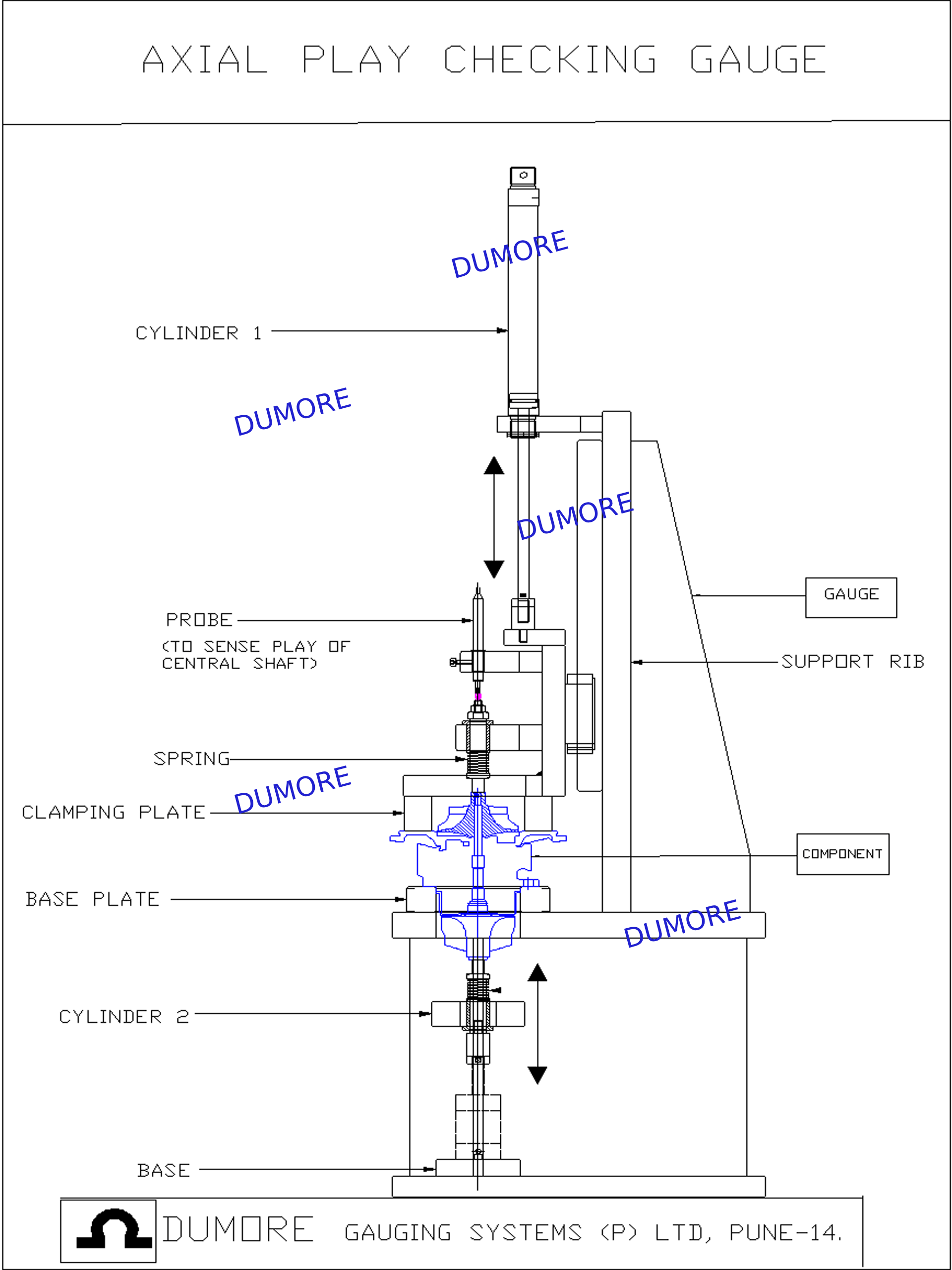

Axial play Automatic Gauging

Description :

- In the Turbo Charger Assembly, the Central Shaft Axial Play Calculation is done automatically in our Gauge - Central Shaft of Turbo Charger

Inspection Steps :

- Two button Start.

- Pneumatic Clamping of outer housing from top.

- Datum value creation.

- Pneumatic Pushing of central shaft upwards.

- Full movement is detected by LDVT Probe.

- Axial Play Calculation

- Both cylinders will automatically release the component.

- Axial Play Calculation is done and displayed.

- Auto Unlock of door for component removal.

Parameters Checked :

- Turbo Charger Assembly, Central Shaft Axial Play Calculation.

Features :

- Full operator safety. All operation will start only after fibre glass doors are closed.

- Air supply is digitally controlled within a range.

- Data can be transferred to computer in real-time for data analysis.

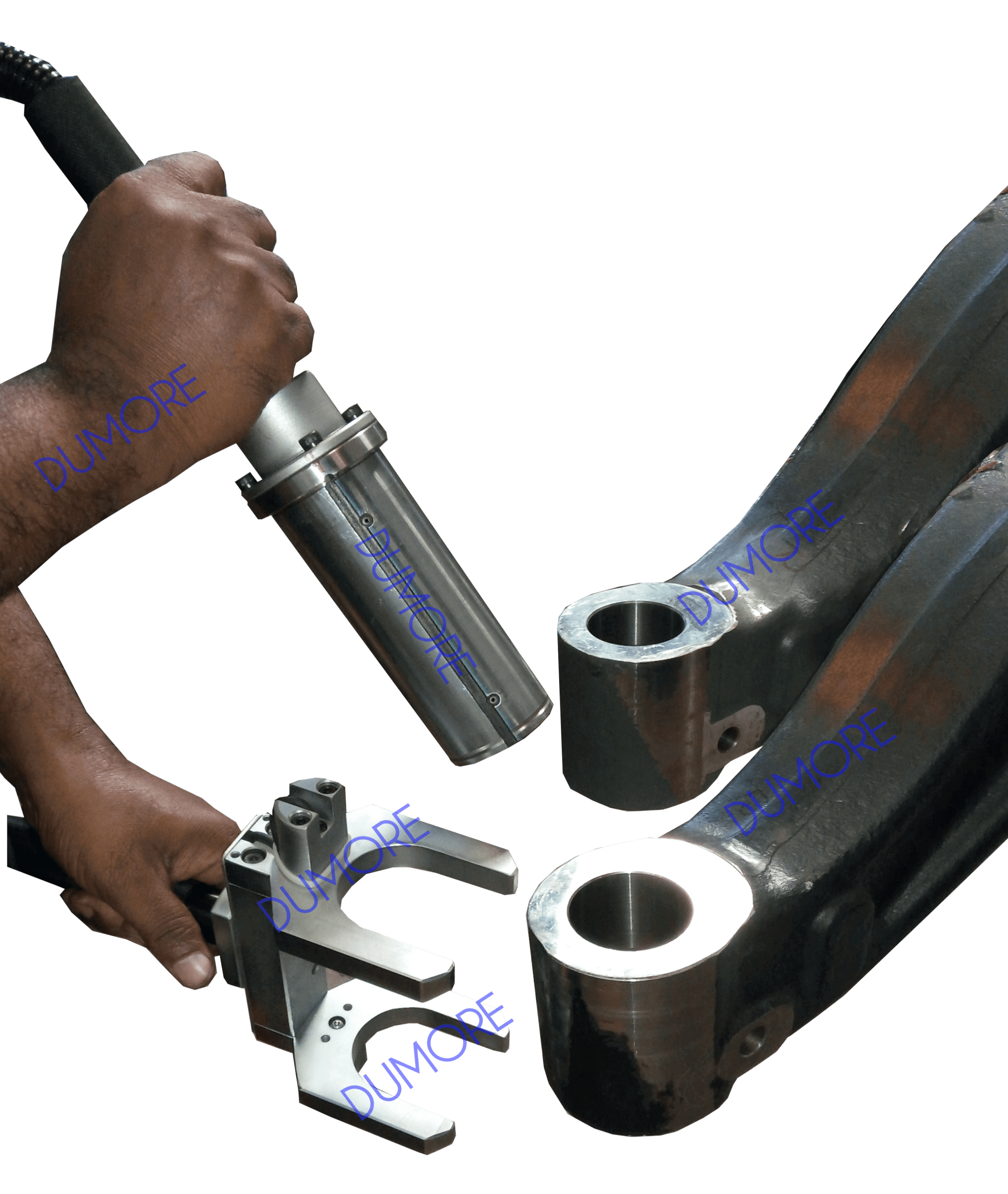

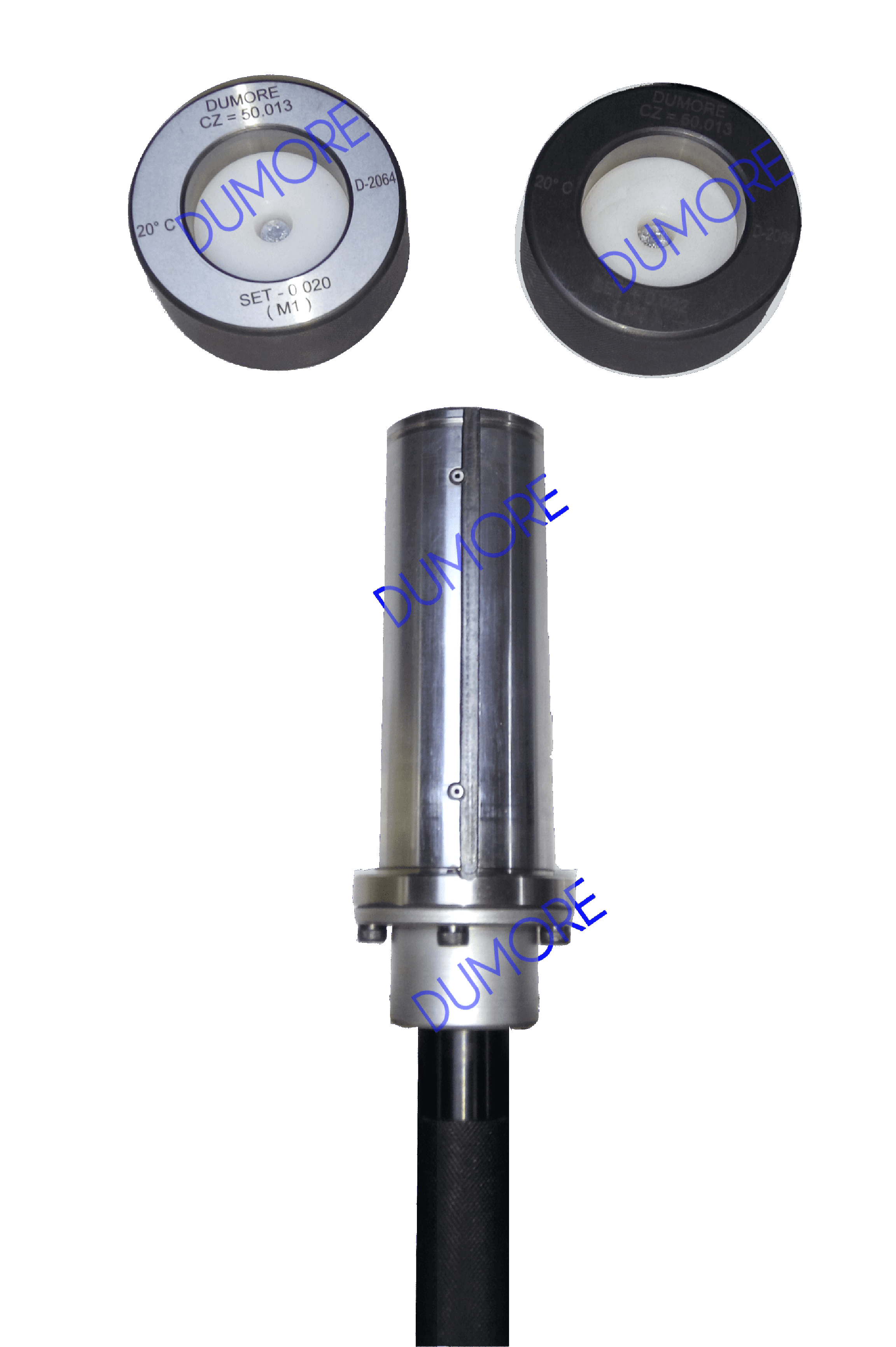

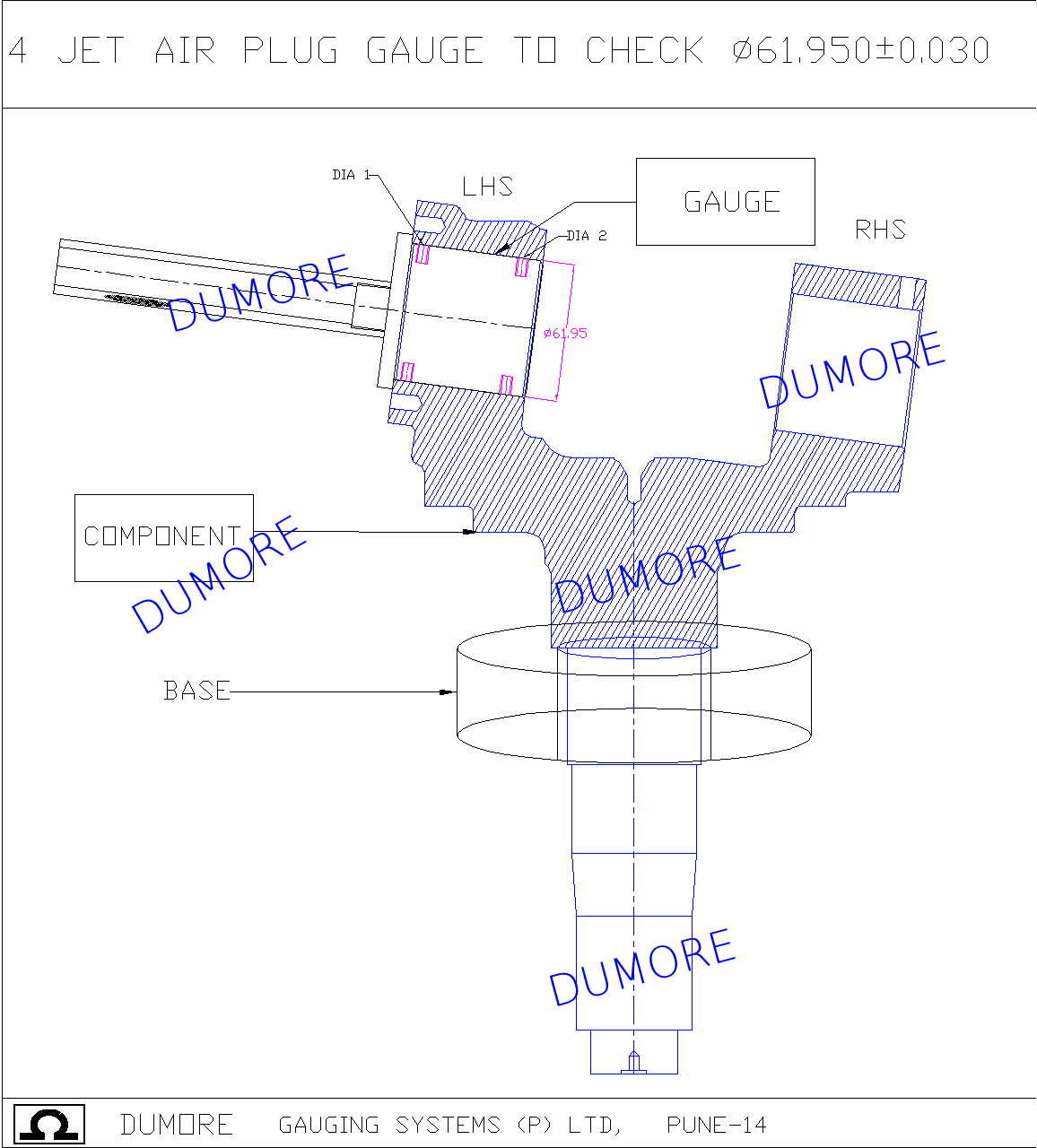

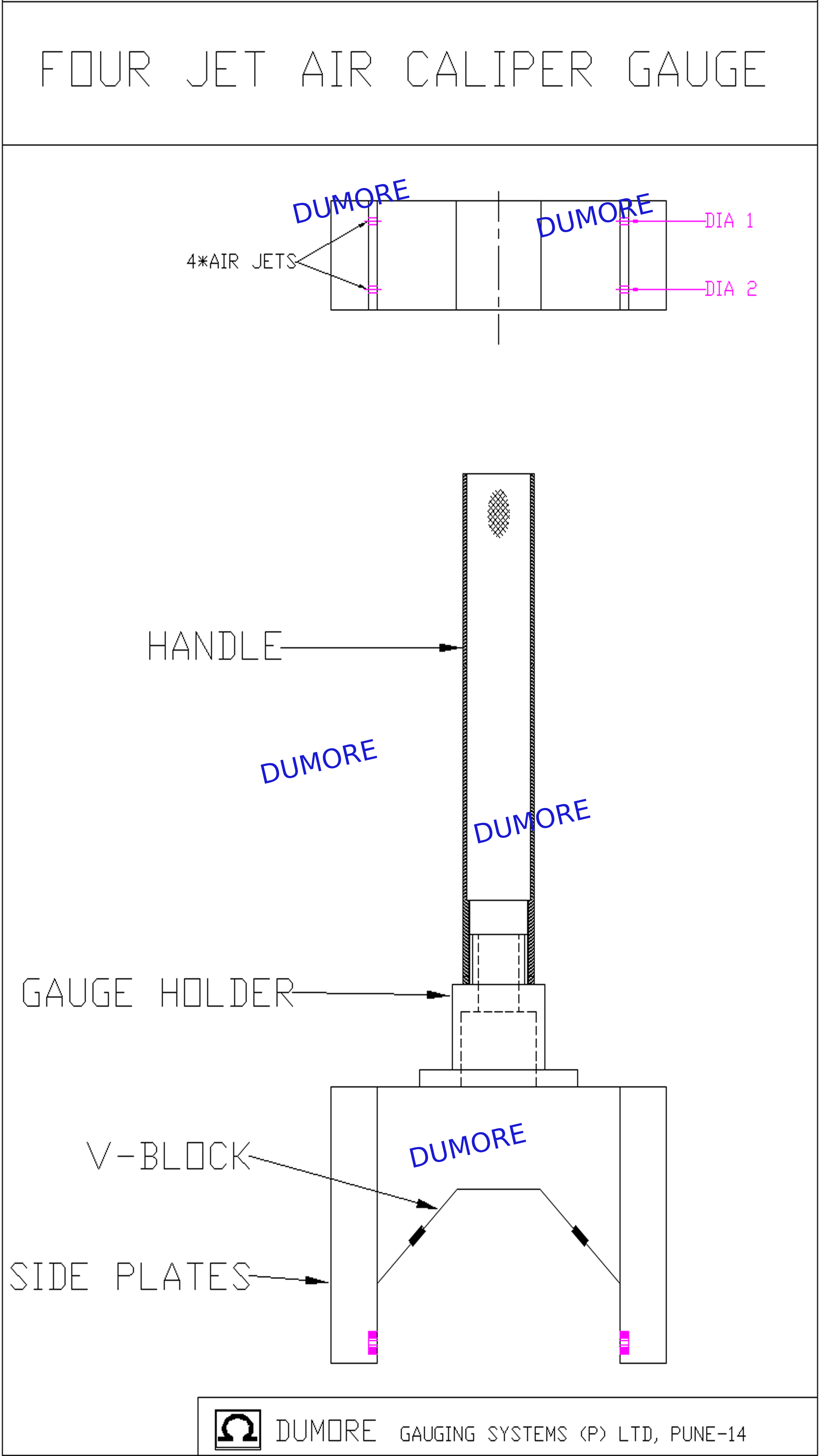

Four Jet Air Plug gauge

Description :

- Four Jet Air Plug gauge to check Diameter and Ovality at Two places with Taper at same time for Knuckle component.

Parameters checked :

- ID- Internal Diameter at Two places

- Taper along full depth of Knuckle

- Ovality at Two places.

Features :

- Very simple & ergonomic in operation.

- All important parameters of I.D. are checked instantly.

- Design is such that both sides of knuckle can be checked very fast.

- Fitted next to Machine output.

- Light weight and durable.

- Small cycle time and very precise.

- SPC system can be integrated.

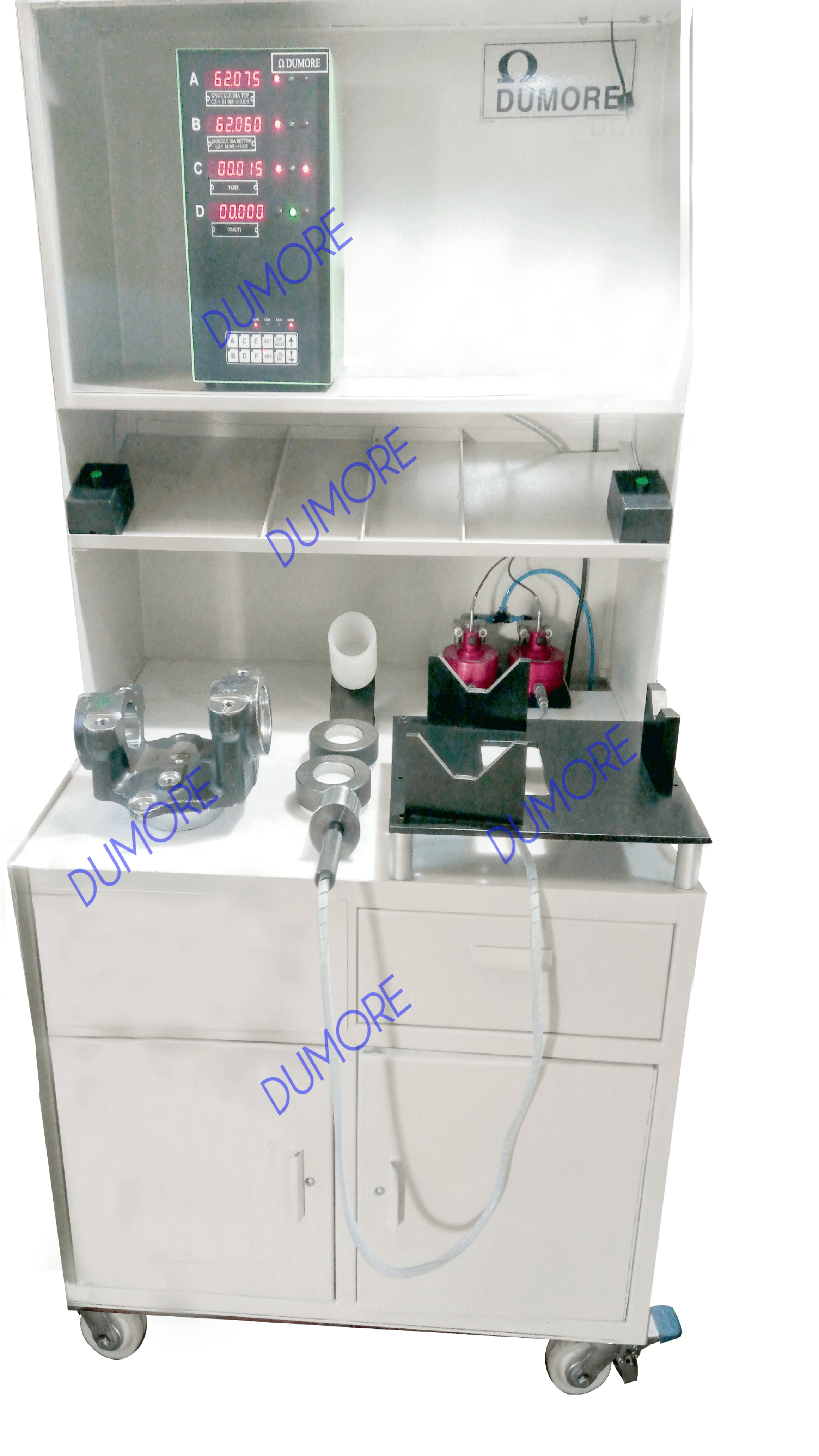

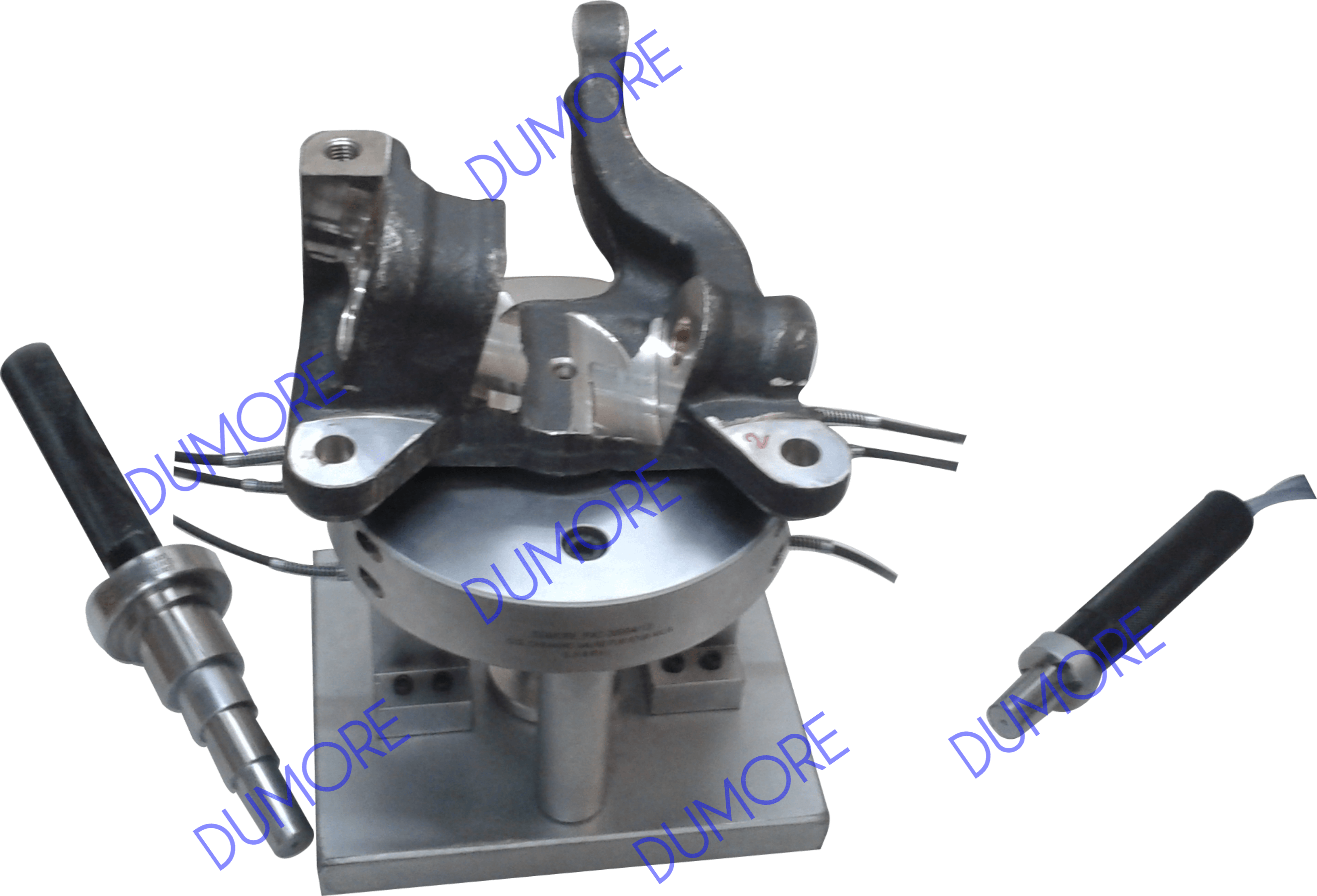

Knuckle component Multi-Gauge

Description :

- This is Computer based Multi-Gauge.

- Gauge is placed into stand for all parameters to be checked instantly.

Parameters checked :

- I.D., O.D. & Ovality at Three places

Features :

- All ODs, IDs, & Ovality are checked at same instant.

- All data is permanently saved in the computer.

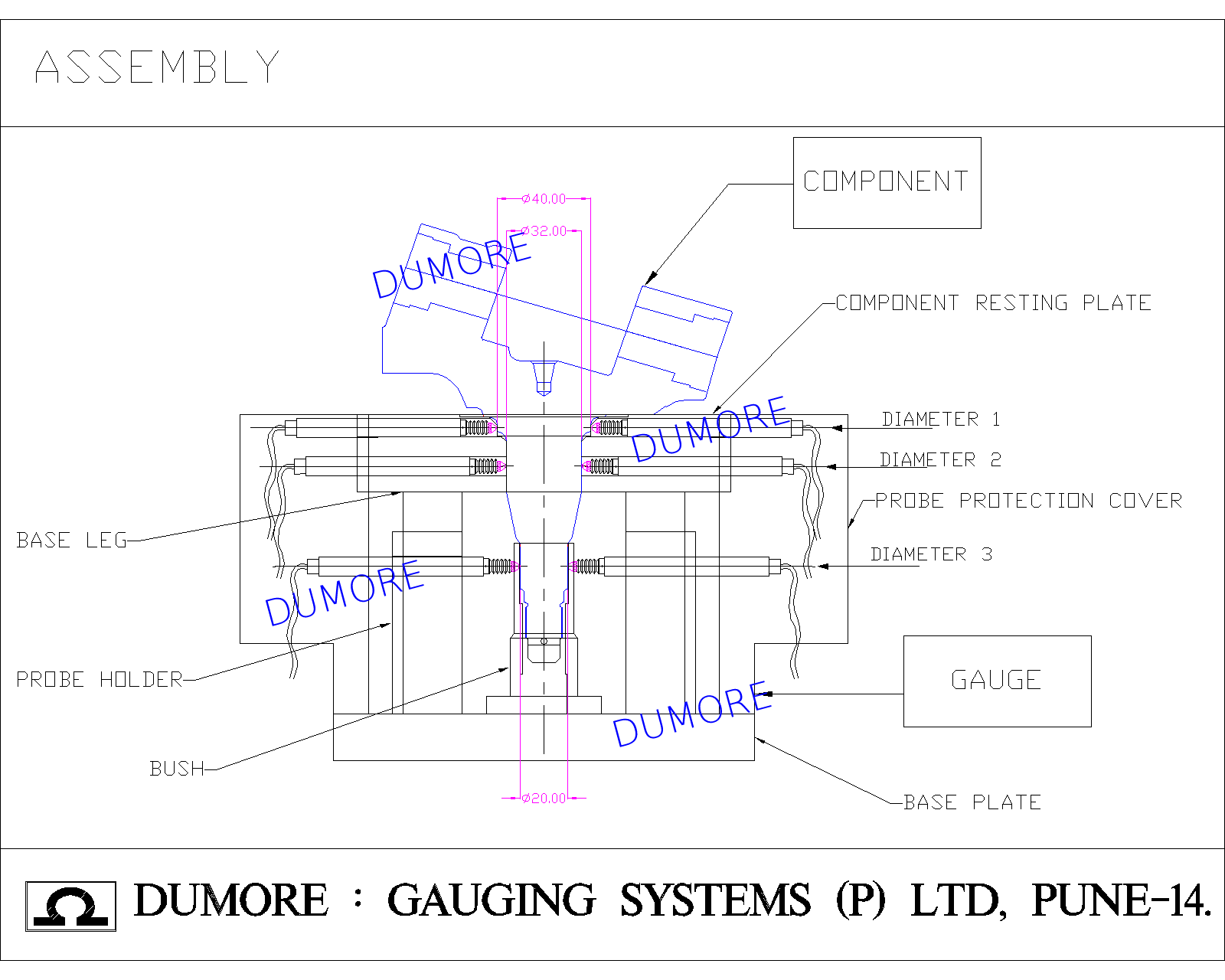

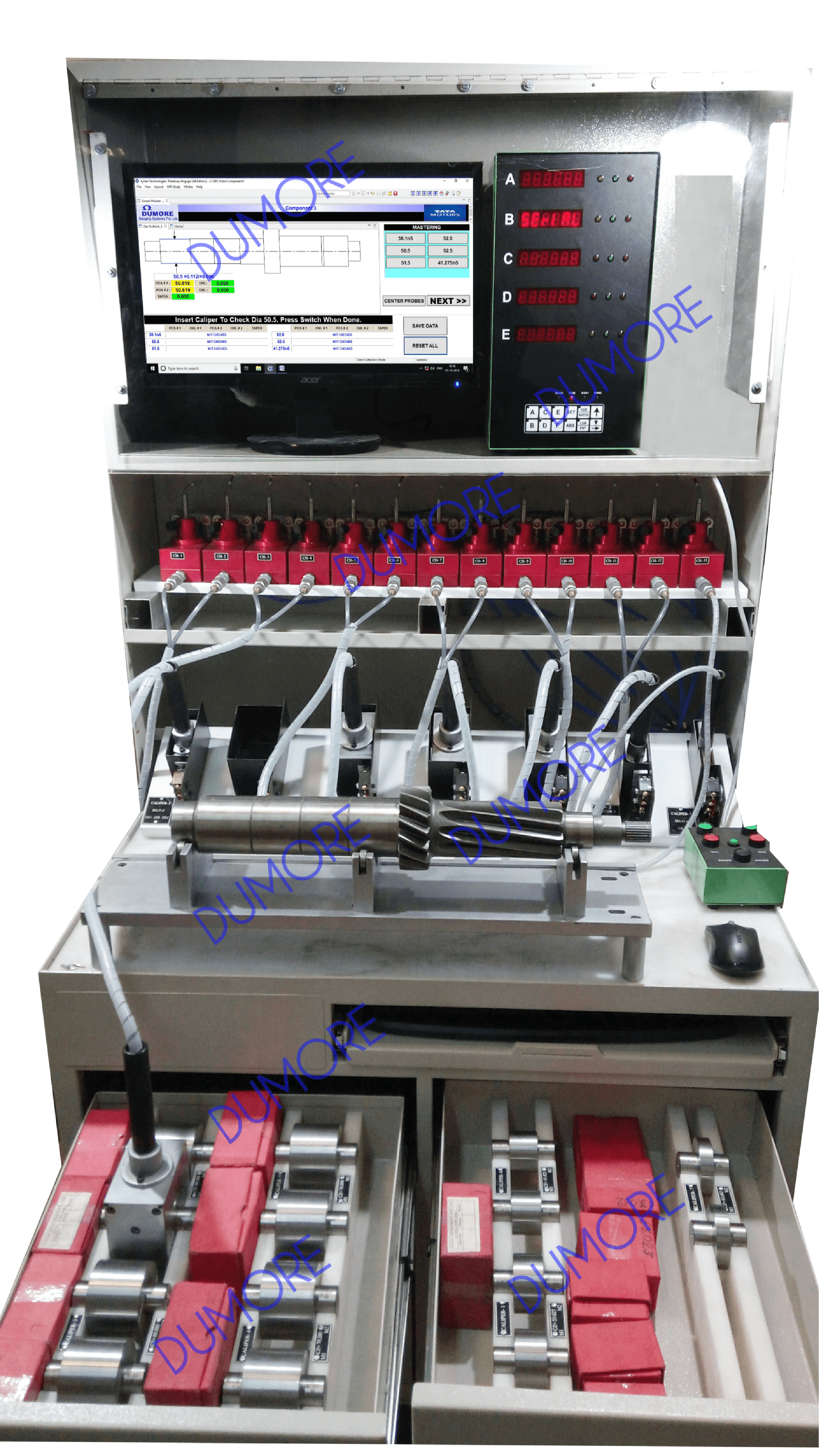

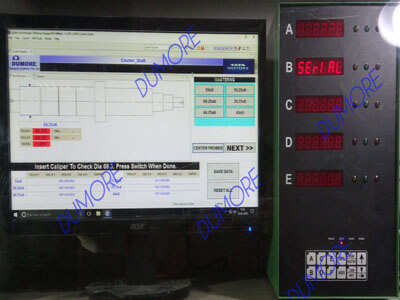

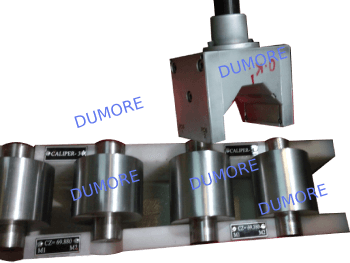

Computerized Shaft All O.D. Inspection System

Description :

- This is Computer based Multi-Gauge with Dumore Micro-processor based Data Receiver/Processor/Display/ Transmitter- All in one

- All O.D.s of the Gear Box Shafts are checked here.

Parameters checked :

- O.D. at Two places for Each Diameter.

- Taper for each Diameter along Full Shaft

- Ovality at Two places for Each Diameter.

Features :

- Five variety of shafts commonized into single gauge station.

- Fitted directly onto Assembly line.

- Light weight and durable gauges.

- Small cycle time and very precise.

- SPC system maintains all records lifelong.

- Operator friendly.

Automatic gauging for Cylinder Head & Block

Description:

- Fully Automatic gauge to check multiple parameters on the component Cylinder Head and Block.

- Parameters are checked from top, bottom & back face of component.

Parameters :

- All IDs, Heights, Center Distance, etc.

Features :

- Fully automated.

- Alpha Numeric marking also done.

- Operator friendly.

- Fitted directly onto Assembly line.

- Light weight and durable.

- Small cycle time and very precise.

- SPC system maintains all records lifelong.

- Operator friendly.

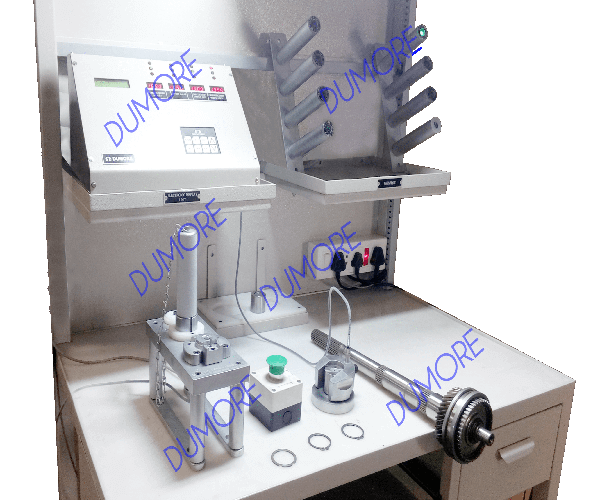

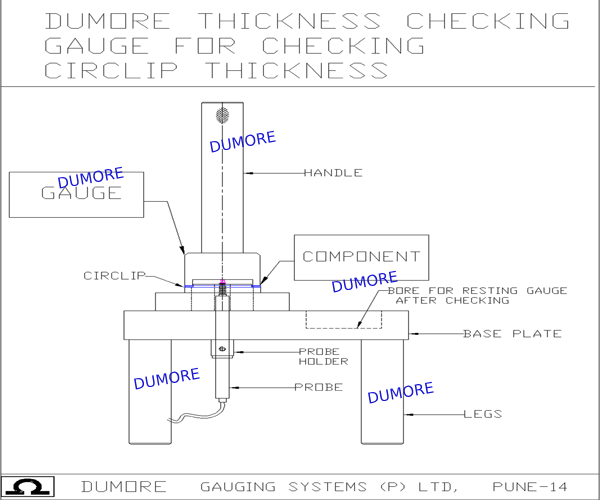

Shim/Circlip Calculating and Selecting gauge.

Description :

- This gauge is for Gear Shifter Shaft Assembly. Very small width within the assembly is checked.

- After Width is checked, on the shim stand light starts blinking for correct shim to be picked. After this, Shim confirmation gauge is used to check thickness of Shim.

- All steps form a closed cycle.

Parameters :

- Slot Width on shaft.

- Indication of which Shim size to be picked up from Rack.

- Circlip thickness.

Features :

- Handlheld gauge for easy and fast operation.

- In-built pokayoke with alarm to reduce operator error.

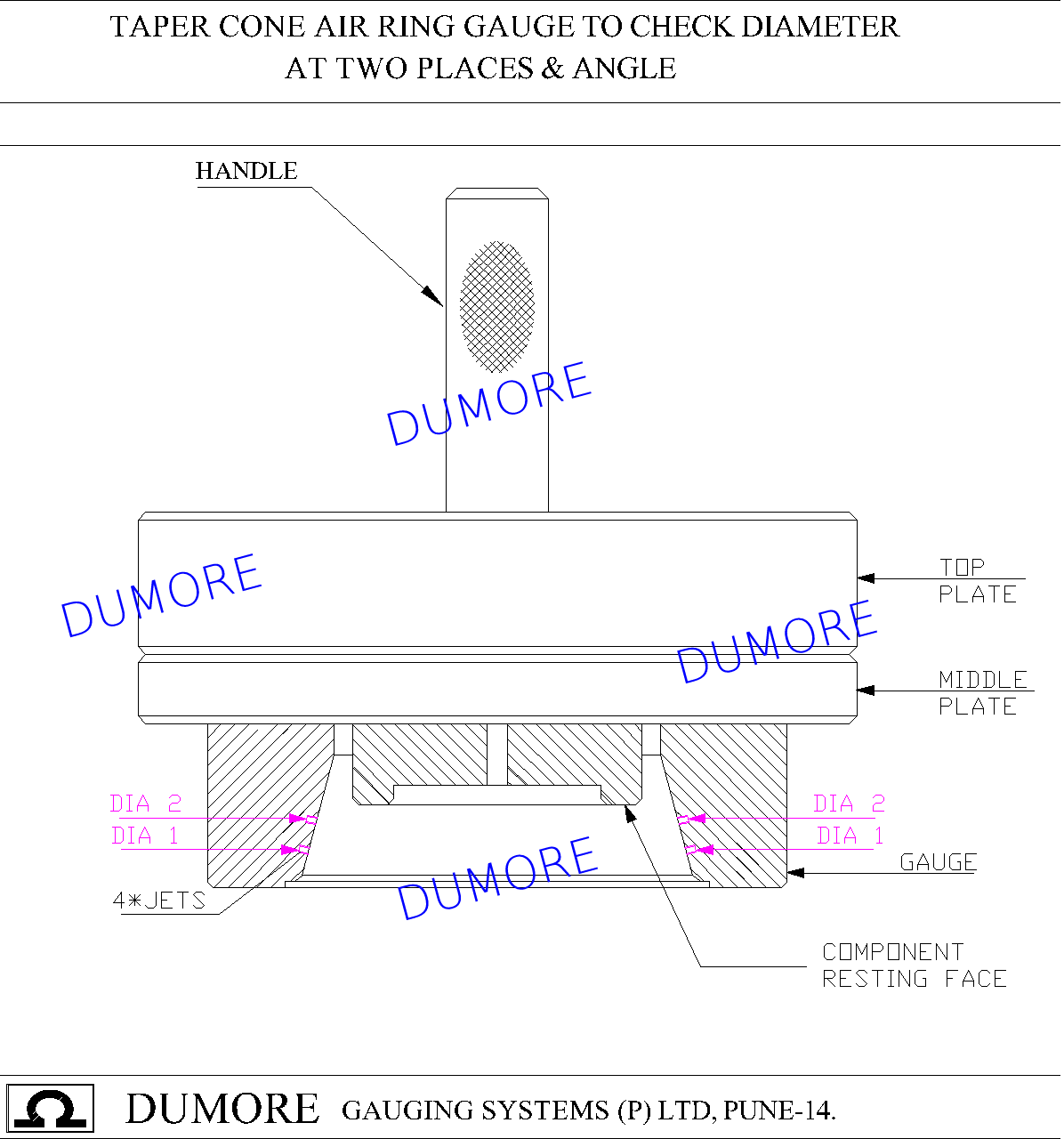

Taper Angle & Gauge Plane Ht./Gauge Dia. checking gauge.

Description :

- We are one of the reputed organization involve in providing superior quality Taper Checking Gauges. These Checking Gauges are appreciated by large number of clients. These products are available in market at most economical rates. Used for very close tolerances checking for parts like Speed Gear, Transmission Shafts, etc.

Parameters checked :

- Taper Cone Angle

- Diameters at Top and Bottom on Taper.

- Gauge diameter at Gauge Plane Height OR

- Gauge Plane Height at Gauge diameter

Features of Taper Checking Gauges:

- To check Taper Cone Angle and displays directly in degrees minutes and seconds and reference diameter at specified height

- Buzzer facility for OK/ reject component

- Auto calibration facility for setting high and low master

- Common gauge set for having same cone dia and cone angle with different heights of component

- Angle will be displayed in degrees min seconds

OTHERS

Special component gauge

- Checking of I.D., O.D., Height and Taper. All parameters are checked simultaneously moment the component is placed on the gauge. Very fast and easy operation.

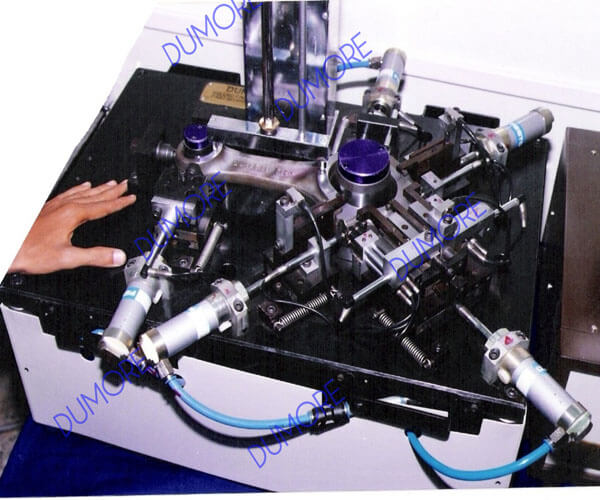

Connecting Rod gauge- Multigauging system.

- This gauge is to check 27 various parameters of Con-Rod like Big End dia, C.D., Bend, Twist, Face Squareness, Taper, Cylindricity and face distance

- Automatic activation of bearing slides and location with the help of pneumatic cylinder, controlled through computer

- SPC control chart facility available with both the option

Connecting-Rod gauge

- Three gauges for three variety of components. Parameters checked- Big-End Dia.

- Small End Dia.

- Bend & Twist.